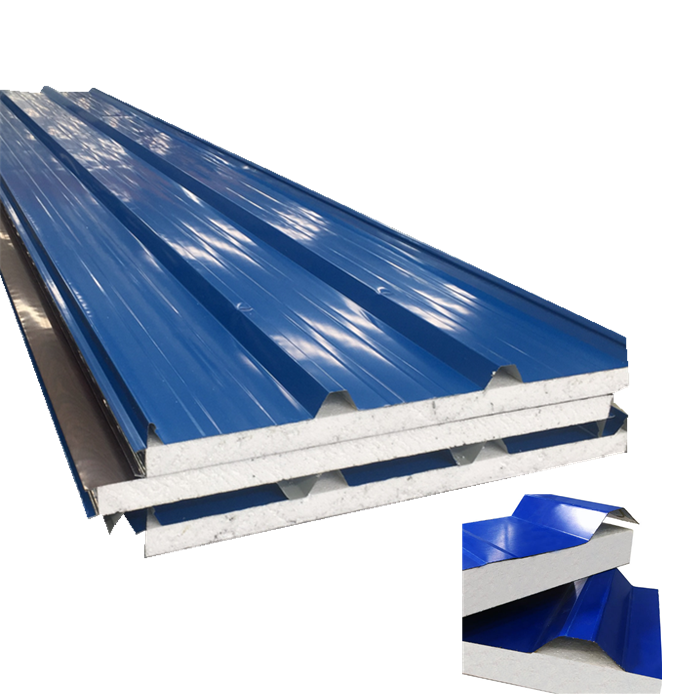

This product uses polyurethane composite core material combined with glass fiber cotton or rock wool, providing good thermal insulation performance. The panels are made of steel with a three-wave peak corrugated surface. Multiple thicknesses and widths are available, suitable for industrial plants, warehouses, cold storage, and other applications. The lap joint connection ensures secure and reliable installation.

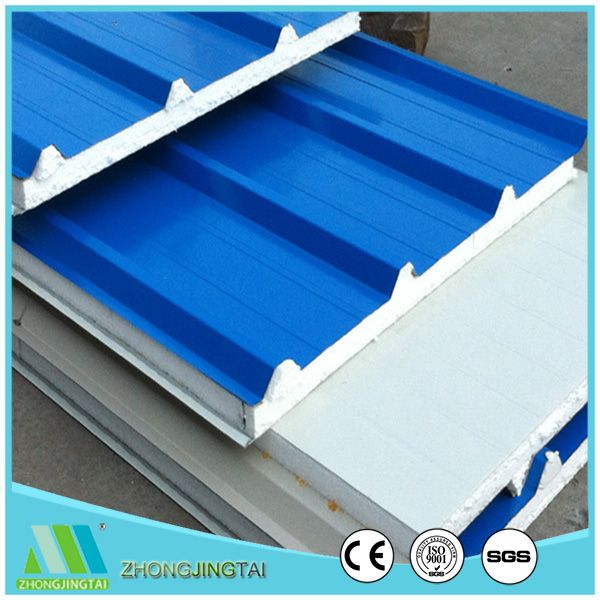

These panels are made of steel outer layers combined with glass fiber cotton or rock wool core material, achieving Class A combustion performance, making them suitable for buildings with high fire resistance requirements. The three-wave peak corrugated surface enhances panel strength and aesthetics. Multiple sizes can be customized to meet diverse engineering needs.

This sandwich panel is available in thicknesses from 50 to 150 mm. The outer steel plate thickness ranges from 0.5 to 0.7 mm, and the inner steel plate from 0.4 to 0.6 mm, balancing structural strength and weight. Panel lengths can reach up to 15 meters, meeting the needs of large-scale continuous roofing or wall coverage.

| Item | Specification |

|---|---|

| Specification (mm) | Standard panel width: 1000 Optional panel widths: 350 - 500 Panel length: ≤ 15000 Standard panel thickness: 50, 75, 100, 150 (other customizations) |

| Outer Surface Morphology | Three-wave peak corrugation |

| Panel Thickness (mm) | Outer steel plate: 0.5 - 0.7 Inner steel plate: 0.4 - 0.6 |

| Connection Feature | Lap joint |

| Core Material Types | PU + glass fiber cotton, PU + rock wool |

| Core Material Density (Kg/m³) | Glass fiber cotton: 64 Rock wool: 100 - 140 |

| Combustion Performance | Class A |

Related Display